There are a number of tests to assess the properties of bituminous materials. The following tests are usually conducted to evaluate different properties of bituminous materials.

- Penetration test

- Ductility test

- Softening point test

- Specific gravity test

- Viscosity test

- Flash and Fire point test

- Float test

- Water content test

- Loss on heating test

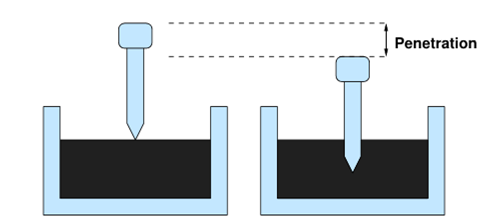

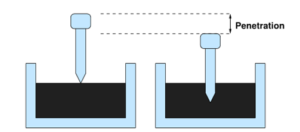

Penetration test

It measures the hardness or softness of bitumen by measuring the depth in tenths of a millimetre to which a standard loaded needle will penetrate vertically in 5 seconds. BIS had standardized the equipment and test procedure. The penetrometer consists of a needle assembly with a total weight of 100g and a device for releasing and locking in any position.

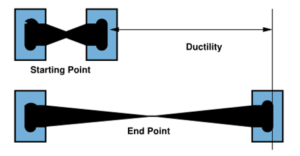

Ductility test

Ductility is the property of bitumen that permits it to undergo great deformation or elongation. Ductility is defined as the distance in cm, to which a standard sample or briquette of the material will be elongated without breaking.

Softening point test

Softening point denotes the temperature at which the bitumen attains a particular degree of softening under the specifications of test. The test is conducted by using Ring and Ball apparatus.

Specific gravity test

In paving jobs, to classify a binder, density property is of great use. In most cases bitumen is weighed, but when used with aggregates, the bitumen is converted to volume using density values. The density of bitumen is greatly influenced by its chemical composition. Increase in aromatic type mineral impurities cause an increase in specific gravity.

Viscosity test

Viscosity denotes the fluid property of bituminous material and it is a measure of resistance to flow. At the application temperature, this characteristic greatly influences the strength of resulting paving mixes. Low or high viscosity during compaction or mixing has been observed to result in lower stability values. At high viscosity, it resist the comp active effort and thereby resulting mix is heterogeneous, hence low stability values.

Flash and fire point test

At high temperatures depending upon the grades of bitumen materials leave out volatile. And these volatile catches fire which is very hazardous and therefore it is essential to qualify this temperature for each bitumen grade.

Float test

Normally the consistency of bituminous material can be measured either by penetration test or viscosity test. But for certain range of consistencies, these tests are not applicable and Float test is used.

Water content test

It is desirable that the bitumen contains minimum water content to prevent foaming of the bitumen when it is heated above the boiling point of water. The water in a bitumen is determined by mixing known weight of specimen in a pure petroleum distillate free from water, heating and distilling of the water.

Loss on heating test

When the bitumen is heated it loses the volatility and gets hardened. About 50gm of the sample is weighed and heated to a temperature of 163 C for 5hours in a specified oven designed for this test.