Ballast is a layer of broken stones, gravel, moorum, or any other granular material placed and packed below and around sleepers for distributing load from the sleepers to the formation. It provides drainage as well as longitudinal and lateral stability to the track. Different types of ballast materials and their specifications are discussed in this chapter.

FUNCTIONS OF BALLAST

The ballast serves the following functions in a railway track.

- It provides a level and hard bed for the sleepers to rest on.

- It holds the sleepers in position during the passage of trains.

- It transfers and distributes load from the sleepers to a large area of the formation.

- It provides elasticity and resilience to the track for proper riding comfort.

- It provides the necessary resistance to the track for longitudinal and lateral stability.

- It provides effective drainage to the track.

- It provides an effective means of maintaining the level and alignment of the track.

TYPES OF BALLAST

The different types of ballast used on Indian Railways are described here.

Sand ballast

Sand ballast is used primarily for cast iron (CI) pots. It is also used with wooden rod steel trough sleepers in areas where traffic density is very low. Coarse sand is preferred in comparison to fine sand. It has good drainage properties, but has the drawback of blowing off because of being light. It also causes excessive wear of the rail top and the moving parts of the rolling stock.

Moorum ballast

The decomposition of laterite results in the formation of moorum. It is red, and sometimes yellow, in colour. The moorum ballast is normally used as the initial ballast in new constructions and also as sub-ballast. As it prevents water from percolating into the formation, it is also used as a blanketing material for black cotton soil.

Coal ash or cinder

This type of ballast is normally used in yards and sidings or as the initial ballast in new constructions since it is very cheap and easily available. It is harmful for steel sleepers and fittings because of its corrosive action.

Broken stone ballast

This type of ballast is used the most on Indian Railways. Good stone ballast is generally procured from hard stones such as granite, quartzite, and hard trap. The quality of stone should be such that neither it should be porous nor it flake off due to the weathering. Good quality hard stone is normally used for high-speed tracks. This type of ballast works out to be economical in the long run.

Other types of ballast

There are other types of ballast also such as the brickbat ballast, gravel ballast, kankar stone ballast, and even earth ballast. These types of ballast are used only in special circumstances.

SIZES OF BALLAST

Previously, 50 mm (2″) ballasts were specified for flat-bottom sleepers such as concrete and wooden sleepers, and 40 mm (1.5″) ballasts for metal sleepers such as CST-9 and trough sleepers. Now, to ensure uniformity, 50 mm (2″) ballasts have been adopted universally for all types of sleepers. Points and crossings are subjected to heavy blows of moving loads and hence are maintained to a higher degree of precision. A small sized, 25 mm (1″) ballast: s. therefore, preferable because of its fineness for slight adjustments, better compaction, and increased frictional area of the ballast.

For uniformity’s sake, the Indian Railways has adopted the same standard size of ballast for the main line as well as for points and crossings. This standard size of ballast should be as per Indian Railways specification. The specification provides grading of ballast from 25 mm to 65 mm, maximum quantity of ballast being in the range of 40 mm to 50 mm size.

REQUIREMENTS OF GOOD BALLAST

Ballast material should possess the following properties,

- a) It should be tough and wear resistant.

- b) It should be hard so that it does not get crushed under the moving loads,

- c) It should be generally cubical with sharp edges.

- d) It should be non-porous and should not absorb water.

- e) It should resist both attrition and abrasion.

- f) It should be durable and should not get pulverized or disintegrated under adverse weather conditions

(g) It should allow for good drainage of water,

(h) It should be cheap and economical.

DESIGN OF BALLAST SECTION

The design of the ballast section includes the determination of the depth of the ballast cushion below the sleeper and its profile. These aspects are discussed as follows.

Minimum Depth of Ballast Cushion

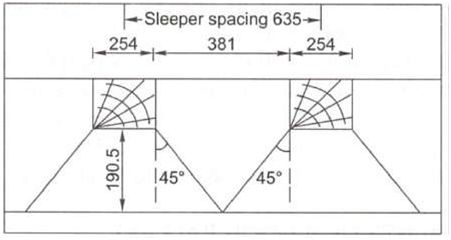

The load on the sleeper is transferred through the medium of the ballast to the formation. The pressure distribution in the ballast section depends upon the size and shape of the ballast and the degree of consolidation. Though the lines of equal pressure are in the shape of a bulb as discussed in, yet for simplicity, the dispersion of load can be assumed to be roughly 45° to the vertical. In order to ensure that the load is transferred evenly on the formation, the depth of the ballast should be such that the dispersion lines do not overlap each other. For the even distribution of load on the formation, the depth of the ballast is determined by the following formula:

Sleeper spacing = width of the sleeper + 2 x depth of ballast